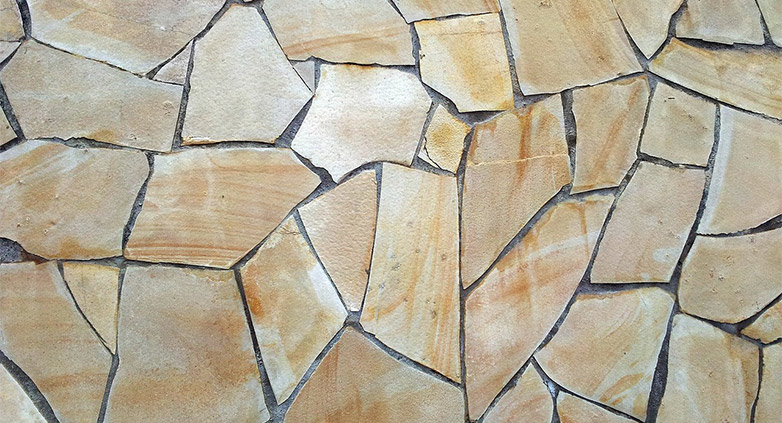

Limestone paving has proven to add elegance and charm to outdoor spaces. Every homeowner wants stone paving that adds aesthetics, structure, character, and class to their patio and exterior landscape. Limestone paving has the style, versatility, and durability you want for your stone paving. It is used on patios, exteriors, or driveways to give a flatter and smoother surface. Limestone is the cornerstone you can’t throw away if you are looking for a hard-wearing surface.

Limestone paving is an essential option if you’re considering ancient exterior aesthetics. The landscape has very soft color variations than most natural stones. It has a high hardness level and delivers high-density colors with fewer holes than other stones. It also has an excellent natural appearance and anti-slip properties. Limestone paving has very high durability making it popular in gardens and walkways. It resists acid-liquid erosion and can be cleaned with a mild alkaline-based solution which preserves the beauty and protects the limestone patio.

What I see is a limestone landscape

W.H. Auden

W.H. Auden said this when he was asked to imagine paradise. Each piece of limestone pavement ages beautifully and can serve as an excellent paver for your home, garden, and patio. This article is the best guide to help you decide if limestone paving is the stone paving you want.

What is Limestone?

Limestone is a natural material found all over the world. It’s a rock made from carbonate and calcium. Limestone forms under the sea; in marine water that is calm, clear, and shallow.

It is a durable natural stone that’s dense and hard-wearing. Limestone can withstand extreme temperatures and come in various colors for roads, patios, and driveways. The color variation is a result of the impurities that are found in the sediment.

More Like This:

- How long before you can drive on a sealed driveway?

- Gravel Driveway on a Slope

- New Asphalt Driveway Issues

Pros of limestone paving

Although limestone has setbacks, it also has a lot of advantages and benefits that make it stand out. When you want to decide on which pavement to use for your roads, driveways, or patios, it’s best to go over the advantages and disadvantages. This act will tell if you are making the right choice or not.

Low- Maintenance

Many people love limestone pavement because it requires little effort to maintain.

Durability

Because limestone is naturally found in caves and mountains, they are durable. When used to pave our roads, gardens, or driveways, they can stand the test of time.

Malleability

Limestone is malleable and can be shaped to fit into garages, gardens, or patios. It enhances the softness and appearance of your environment.

Limestone is Eco-friendly.

You don’t have to worry about harming the environment when you use limestone as a paving material. Limestone is sustainable as it doesn’t emit carbon into the atmosphere.

Water Absorption

Limestone absorbs minimal amounts of water and can tolerate extreme weather conditions. It is a good option to explore for homeowners living in a rainy environment.

Cons of Limestone Pavement

Salt can cause the scaling of the limestone.

Sand is needed to ice the limestone drive or walkway. It can cause splitting, flaking or cracking, and fragmentation of the pathway.

Poor Foundation.

Limestone foundation capability is poor. When you use limestone to construct dams, roads, or driveways, it could cave in at any time due to changes in water pH and dissolve.

Related Articles:

Is limestone paving slippery when wet?

The question of whether limestone paving is slippery or not depends on the finished surface of the pavement. Usually, limestone has a smooth surface, and when wet, it is slippery. However, it enhances and supports the surface when limestone pavement is finished with other gripping finishers. Like any stone, when the surface is polished, they become slippery when wet.

Natural stones are not inherently risky and are formed to allow you to hit rock bottom. But to be on the safe side and to avoid any possibility of hurting one sledge, you should consider a honed finishing. Honed or sand-blasted stone has a smooth but textured and firmer finish. It has less sheen and doesn’t reflect light. But the surface is strong, firm, and safer during rainy seasons or when wet floors are.

A honed finish prevents you from hitting rock bottom. It helps your driveway or walkway pavement to retain its footing and is slip-resistant and perfect for outdoor use.

Do you need to seal limestone paving?

You need to seal your limestone pavement to last the test of time. Sealing maintains the natural appearance of the stone and prevents stains.

Do you need to clean your limestone paving?

Limestone is a popular material used to pave walkways, driveways, and patios. Because of how shiny and beautiful the surface is, it’s used indoors to enhance the beauty of the environment. However, this smooth and eye-catching paving material would get clean quickly if not maintained well. Learning how to clean your limestone pavement will help prolong its life and keep it cleaned.

Before cleaning your limestone pavement, it’s good to consider its features. Limestone paving reacts with acid because it’s made up of calcium carbonate. When you decide to clean your limestone exterior, walkways, or patios, you should use substances that won’t accumulate and react with your pavement. When you bear all of these in mind, your limestone will look perfectly clean and outstanding after cleaning.

Does limestone pave stain?

Limestone is a durable material that can easily stain if not maintained properly. Most limestone pavements are coated with sealing substances, preventing them from oil or substance stains. If you find any stains on your sealed pavement, it’s possible that the seal is wearing off and needs to be renewed. The key to preserving your pavement is careful cleaning, maintenance, and surface protection.

A limestone cleaner or stain removal will help remove any stain on your pavement. It will carefully clean and remove any oil stain without scratching it or disrupting the natural color of your pavement. If you are unsure about carefully cleaning your pavement, contact a professional limestone cleaner to do the work.

Limestone paving colors and ideas

Midnight black limestone is smooth, flat, and slip-resistant, with a uniform appearance. It is easy to lay and beautiful. This carbon limestone paving has been calibrated to 25mm.

Dove grey limestone paving with a consistent depth of 22mm. This dove grey paving saves you time and money because it’s easy and quick to lay. Quality maintenance can help your limestone patios last the test of time.

Read More:

- How long does a tar and chip driveway last

- Decomposed Granite Driveway

- Having A Crushed Concrete Driveway

- Driveway Apron

Kota green limestone gives your patio or exterior a brilliant appearance. It comes in different sizes.

Kota Blue Limestone paving. This blue blend of Kota ocean limestone paving makes your patio or exterior beautiful. Black accessories enhance the beauty of this ocean.

This limestone gives your patios and exterior a traditional vibe. It’s brilliant and decorated with cream, white, and grey patches.

How to lay limestone paving

Before laying your limestone paving, you must cut out your limestone slabs. This process is the most challenging due to the toughness of the stone; regardless if you have the right tools, it will help simplify the process for you. To cut your stone, you must:

- Measure your slab with a pencil and ruler. Ensure you measure the correct dimension or the patterns you want to create.

- With a diamond floor saw, cut off your slabs. You will want to take your time cutting to avoid destroying the slabs.

- When you are done cutting, you will need to smooth out the edges of your slabs. We want to have the best pavement and not some rough work.

Now that we have all our slabs ready, it’s time to get into the main job. Laying your slab by individually bedding each slab into a full-mortar bed can be exciting. We will work you through the steps involved.

The mortar bed you need to lay your slab is usually made up of six parts soft sand, one part cement, six parts sharp sand, and only one part cement. A good mix will provide a solid foundation for your limestone patio. An electric or petrol mixer will make the mix more accessible and practical.

A step-by-step guide to laying your limestone paving:

- The mixture to be spread must be more profound than the slab. Make sure the layer is 50mm thick.

- Gently lay your slab down onto the bed, using a rubber mallet to go over the surface until it is leveled.

- Place the rest of the slab, and go over the surface with a rubber mallet. Ensure you leave a gap of 10-12mm between each slab.

- With mortar joints, fill up the gaps in between your slabs.

- A pointing mortar is made from a mixture of one part of cement with six parts of sand. With a pointing trial, insert your mortar into the joints carefully.

- Using a stiff brush, remove any excess from the surface before it tries off.

Related Articles:

- How To Paint Concrete Patio

- How To Clean Concrete Patio

- Alternatives to Concrete Driveway

- Green Driveway

- Is 2 inches of Asphalt Enough For a Driveway

Conclusion

Your paving choice for your patios and exteriors should depend on your preference, the style you want to achieve, the durability, maintenance level, property type, and, of course, the result.